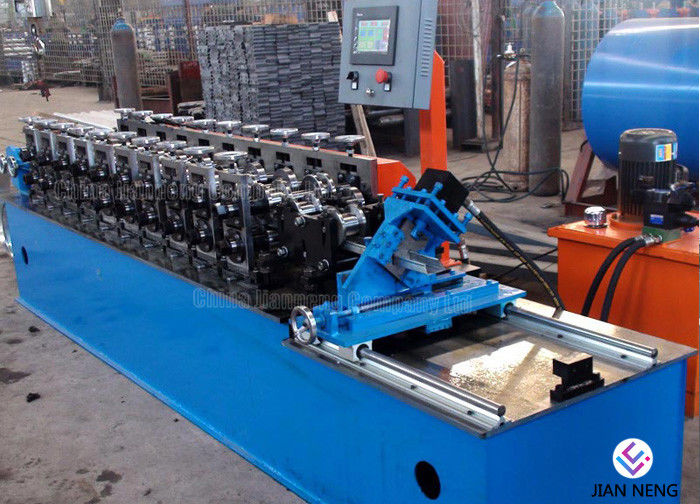

Steel Sheet Roll Forming Machine PPGI GI IBR Trapezoid , Roof Sheet Rolling Machines

Description & Application:

1. Automatical Steel Roof Roll Forming Machine with Cr12 cutting blade by Siemens PLC Control System

2. Roofing Sheet Roll Forming Machine With Speed 0 - 20m / min For Construction Material

3. Corrugated Roof Roll Forming Machine with Chain Drive and PANASONIC Transducer

4. Steel Tile Roof Panel Roll Forming Machine With Hydraulic Control System For Automotive

5. 380V 50Hz High Speed Metal Roof Panel Roll Forming Machine With Hydraulic Control System

Specification / Technical Parameter

| Item |

Steel Sheet Roll Forming Machine PPGI GI IBR Trapezoid , Roof Sheet Rolling Machines |

| Coil Material |

Coil width |

Custom-made, 1000/1200 /1250 mm |

| Sheet thickness |

0.3-0.8 mm |

| Yield Strength |

350-500 Mpa |

| Material |

PPGI, Color Steel, GI. |

| Decoiler / Uncoiler |

Decoiler Type |

Manual or Hydraulic or Auto Type |

| Coil Weight |

5 tons |

| Coil Width |

Max. 1250mm |

| I.D |

440-530mm |

| O.D |

Max.1500mm |

| Steel roof forming machine |

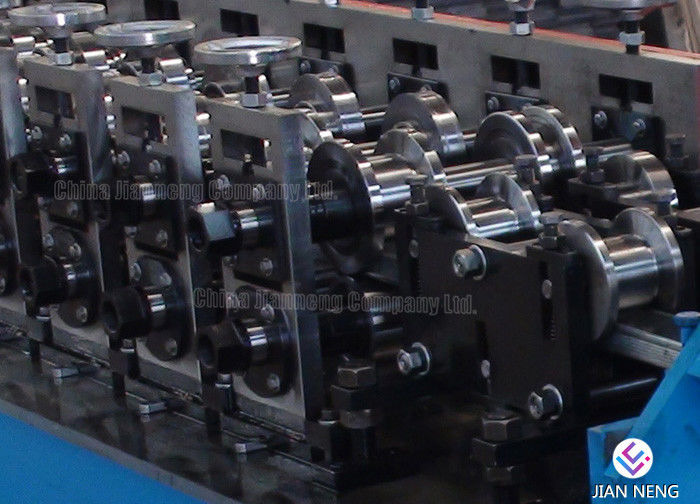

Forming Stations |

13-22 Stations ( Depend on Profiles ) Usually:18 Stations |

| Roller material |

45# steel, surface coated with 0.05mm hard chrome |

| Diameter of shaft |

76mm |

| Shaft material |

High grade 45# steel |

| Drive type |

Chain transmission---16A |

| Sprockets |

Quenched and black treated |

| Forming speed |

0-20m/min |

| Speed adjust |

Panasonic VFD |

| Main power |

5.5KW |

| Cutting |

Cutting type |

Hydraulic Scissor cutting |

| Cutting Die Material |

Cr12Mov steel, HRC58-62 |

| Cutting power |

4 KW (Hydraulic station) |

| Cutting Tolerance |

10m+/-1.5mm |

| Encoder |

OMRON Brand |

| Electrical control |

PLC |

Panasonic Brand |

| Inverter |

Siemens Brand |

| Touch screen |

Panasonic |

| Operation type |

Touch screen & Button |

| Main units |

Schneider |

| Hydraulic Station |

Hydraulic Units |

Famous Chinese brand |

| Runout Table |

Table type |

Simple non power type |

| Function |

To support the finished panel |

Machine composition of Steel Sheet Roll Forming Machine , Roof Sheet Rolling Machines

1. Decoiler -------------------------------------------------- 1 Unit

2. Film covering device --------------------------------- 1 Unit

3. Feeding guide ------------------------------------------ 1 Unit

4. Main roll forming machine --------------------------- 1 Unit

5. Hydraulic pressing device --------------------------- 1 Unit

6. Hydraulic cutting device ------------------------------ 1 Unit

7. Hydraulic Station ---------------------------------------1 Unit

8. PLC computer control ---------------------------------1 Unit

9. Output table ----------------------------------------------1 Unit

Working Follow:

Decoiler --- Feeding Guide --- Film Covering --- Roll Forming --- Pressing --- Cut-to-length --- Run out table

Feature & Advantages:

Glazed Tile Corrugated Steel Roofing Sheet Roll Forming MachineWith 18 Forming Stations

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!