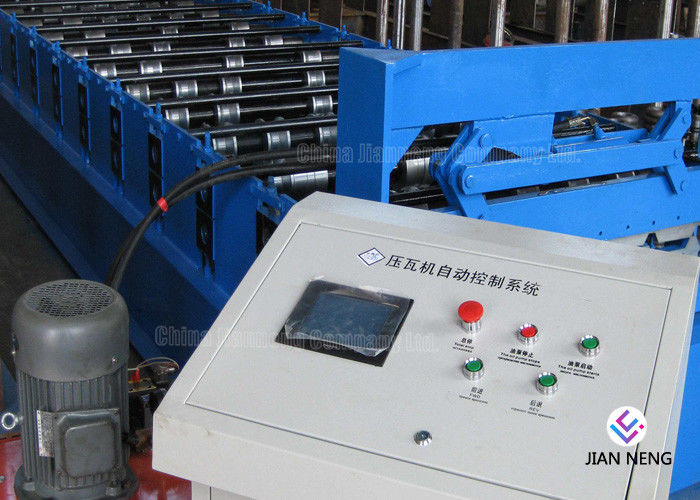

380V Wall Panel Roll Forming Machine , GI PPGI Steel Profile Making Machine High Speed

Description of Wall Panel Roll Forming Machine:

Wall and roof panel roll forming machine is mainly producing steel roof/ wall sheet .The final products have two types,corrugated sheet and trapezoidal sheet. As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing..

The wall and roof roll forming machine can work 16-24 hours per day, motor perform good.

(1) Material Thickness: 0.3-0.8mm PPGI and GI

(2) NO. of roller Stations: 18groups

(3) Material for Rollers: high grade 45# steel polished and coated with chrome HRC55-60°

(4) Material for shaft: high grade 45# steel polished and coated with chrome HRC55-60°

(5) Diameter of shaft: 70mm

(6) Frame panel thickness: 20mm

(7) Bottom frame: 350 H-section steel

(8) Motor Power: 5.5kw

(9) Driven type: 1.0"Chain

Specification / Technical Parameter

| 1 |

Suitable raw material |

PPGI/PPGL/GI/GL Steel Coils |

| 2 |

Thickness of coil sheet |

0.3-0.8mm |

| 3 |

Feeding Coil width |

1000mm/1200mm |

| 4 |

Effective width |

800mm/1000mm |

| 5 |

Under frame |

350H-beam |

| 6 |

Diameter of Soild shaft |

70mm, high grade 45# steel, finish turning, cylindrical grinding, with keyway |

| 7 |

Roller |

High grade 45# steel, processed by CNC lathe, Quenched and tempered treatment,

hard chrome coated 0.05-0.07mm

|

| 8 |

Thickness of middle plate |

Guide pillar memorial archway |

| 9 |

Forming stations |

16 |

| 10 |

Drive type |

By chain(1.0 inch) link bearing model 6210 |

| 11 |

Power of main motor |

4kw with Cycloidal reducer, Lichao, Shanghai |

| 12 |

Power of pump station |

4kw, Lichao, Shanghai |

| 13 |

Forming speed |

About 15-20m/min |

| 14 |

Hydraulic cutting |

Controlled by PLC |

| 15 |

PLC |

DELTA, TAIWAN / Mitsubishi, Japan |

| 16 |

Material of cutting blade |

Cr12Mov, quenching 58-62℃ |

| 17 |

Frequency converter |

It has the advantage of slowing down before cutting, to ensure the

length accuracy(±1mm, far better than industrial

standard ±3mm).

|

| 18 |

Switch |

CHNT |

Components of glazed tile roll forming machine:

| Decoiler |

1set |

| Feeding & guiding device |

1set |

| Main roll forming machine |

1set |

| Hydraulic cutting system |

1set |

| Controlling system |

1set |

| Run out table |

1set |

Installation and Training:

① If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

② Without visiting, we will send you user manual and video to teach you to install and operate.

③If buyer needs our technician to go to your local factory,please arrange round trip tickets, food and hotel and everyday salary USD100, visa cost and necessary things.

FAQ:

1. How to get a quotation?

a.Give me the profile drawing and thickness,this is the important.

b.Other specific requirements is welcome, such as the speed,power and voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping delivery.

3. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send new to replace for free,but you need to pay the express cost yourself. after warranty period,we can negotiate to solve the problems,we supply the technical support for the whole life of the equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!