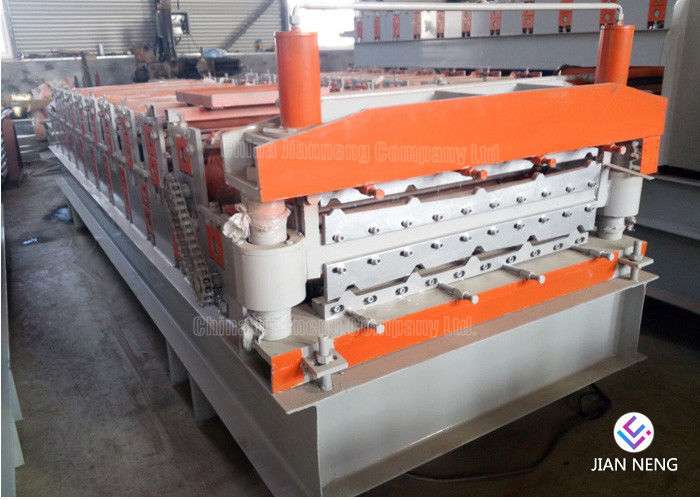

Warehouse Building Material Roll Forming Machine Metal Roofing Machine PPGi GI Material

Description & Application:

The tiles produced by this machine are widely used in all kinds of factories, houses, warehouses and simple steel shed, and with beautiful appearance, high efficiency and reliable working.

Glazed tile, Roof Tile, Metal roof tile; steel roof tile; color steel tile; color glazed tile; wave tile; steel roofing sheet; metal roof panel; steel roof panel; roof wall cladding; roof cladding; wall cladding

Machine Components of Warehouse Building Material Roll Forming Machine Metal Roofing Machine PPGi GI Material

1. Decoiler ---------------------------------------------- 1 Unit

2. Feeding guide -------------------------------------- 1 Unit

3. Main roll forming machine ------------------------ 1 Unit

4. Hydraulic pressing device -------------------------1 Unit

5. Hydraulic cutting device --------------------------- 1 Unit

6. Hydraulic Station ----------------------------------- 1 Unit

7. PLC computer control ------------------------------1 Unit

8.Output tables ---------------------------------------- 2 Units

Work Flowing:

Decoiler --- Fedding Guide --- Film Covering --- Roll Forming --- Pressing --- Cut-to-length --- Run out table

Specification / Technical Parameter

| Series |

Details |

Parameter |

|

Metal roofing machine / Roll forming machine

|

Guiding&leveling device

|

Placed on the machine by seller |

| Shaft numbers:11pcs |

| Shaft diameter:80mm |

| Shaft material: 45# steel |

| Drive power:5.5kw |

| Rolling shaft material |

45# STEEL |

| Shaft diameter |

90mm |

| Roller material |

GB-Cr15 with heat treatment |

| Rolling station |

15 stations |

| Machine frame |

Cast iron vertical structure |

| Machine body |

400# H steel welded |

| Bearing |

Chinese famous brand Harbin |

| Work power |

22kw |

|

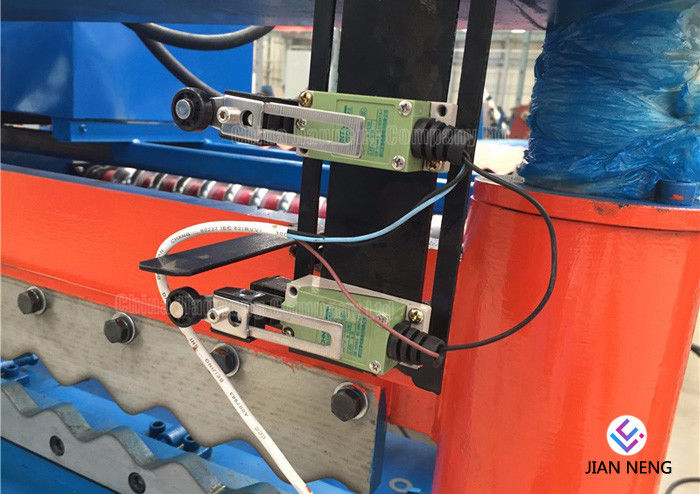

Control system

|

Frequency brand |

Delta from Taiwan |

| PLC brand |

Delta from Taiwan |

|

Hydraulic system

|

Work type |

Hydraulic |

| Punch mode |

Four pillar hydraulic powered punching system |

| Driving method |

By Cylinder |

| Motor power |

22kw |

| Mold material |

GB-Cr12 |

| Mold quantity |

2 sets |

| Punching frame |

1 set |

| Press power |

80T |

| Cutting length tolerance |

±1.5mm |

Feature & Advantages:

Warehouse Building Material Roll Forming Machine Metal Roofing Machine PPGi GI Material

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!