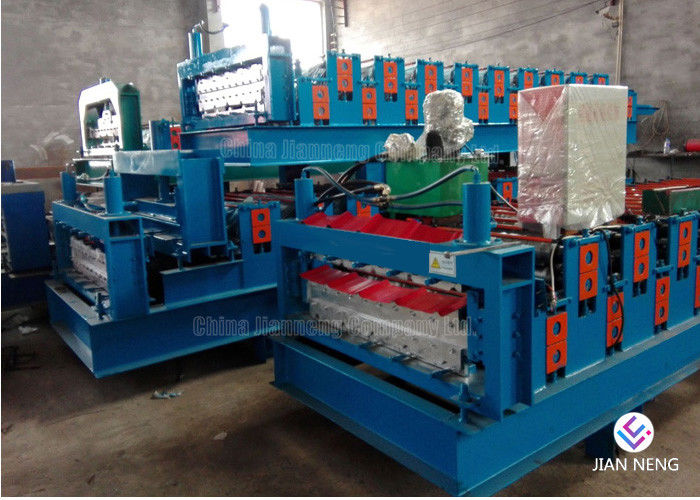

Roof Tile Machine Glazed Tile Roll Forming Machine Metal Roll Forming Machine

Introduction:

1. Suitable for material with thickness 0.5-0.8mm

2. Shafts manufactured from 45#,Main shaft diameter=φ75mm,precision machined

3. Motor driving,Gear chain transmission, 14 steps to form.

4. Main motor=5.5KW , Frequency speed control. Forming speed approx.5-8m/min

5. PLC Control System (Touch screenbrand:German Schneider Electric/Taiwan WEINVIEW,

6. Inverter brand:Finland VOCAN/Taiwan DELTA/ALPHA,Encoder brand:Japan Koyo/OMRON)

7. Combined with: PLC, Inverter, TouchScreen, Encoder, etc

8. Cut-to-lengthtolerance≤±2 mm

9. Control Voltage 24V

10.User's manualin English

Components of Roof Tile Machine Glazed Tile Roll Forming Machine Metal Roll Forming Machine

| MACHINE LIST--WHOLE LINE |

| No. |

Item |

Unit |

Qty |

| 1. |

Manual decoiler |

set |

1 |

| 2. |

Main forming machine |

set |

1 |

| 3. |

PLC Control box |

set |

1 |

| 4. |

Hydraulic pump |

set |

1 |

| 5. |

Cutting system |

pcs |

1 |

| 6. |

Output table |

pcs |

1 |

Feature & Advantages:

Roof Tile Machine Glazed Tile Roll Forming Machine Metal Roll Forming Machine

1. Good quality: We have a professional designer and experienced engineer team.And the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation:All machine cotrolling by PLC computer controlling systerm.

5. Elegant apperance:Protect the machine from rust and the painted colour can be customized

6. Reasonable price:We offer the best price in our industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!